Authors

Bill Bekenn & Ray Hooper

Abstract

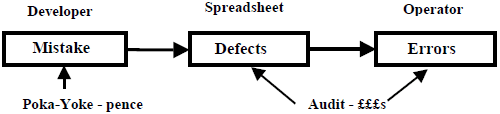

Whilst not all spreadsheet defects are structural in nature, poor layout choices can compromise spreadsheet quality. These defects may be avoided at the development stage by some simple mistake prevention and detection devices.

Poka-Yoke (Japanese for Mistake Proofing), which owes its genesis to the Toyota Production System (the standard for manufacturing excellence throughout the world) offers some principles that may be applied to reducing spreadsheet defects.

In this paper we examine spreadsheet structure and how it can lead to defects and illustrate some basic spreadsheet Poka-Yokes to reduce them. These include guidelines on how to arrange areas of cells so that whole rows and columns can be inserted anywhere without causing errors, and rules for when to use relative and absolute references with respect to what type of area is being referred to.

Sample

The goal of a Poka-Yoke device is to eliminate defects by preventing mistakes from occurring or at least detecting them at source rather than correct, at much greater cost, by audit when they become defects or errors.

Publication

2009, EuSpRIG